42

Guardian Air/Vacuum Valves

for Vacuum Protection

in Drip Irrigation

In drip irrigation, especially subsurface drip irrigation,

vacuum prevention is essential, even at very low negative

pressure, for the prevention of suction of dirt through

drippers, as well as for the prevention of damage to piping

and accessories.

There are three major causes for the formation of vacuum

cavities in manifolds from which dripper laterals emanate

(distribution manifolds)

and in manifolds to which they

drain

(collection manifolds)

.

1. At sudden pump stoppage or valve shut-off, water

column separation occurs after the inline isolating

valve and at peaks, because water supply is suddenly

VWRSSHd \HW WKH H[iVWinJ ZDWHU PDVV FRnWinXHV WR ÁRZ

driven to the forces of inertia. Vacuum cavities are, thus,

developed, exerting negative pressure and suction.

2. At system drainage, if air is not admitted at the rate water

is drained, vacuum cavities form, exerting negative

pressure and suction. In extreme cases, this can result

in pipe or accessory collapse.

3. At pipe or accessory burst

EOind Áanges risers Rr Rn

Oine isROating YaOYes EreaNing RII IRr instanFe

, water is

dUDinHd VRPHWiPHV DW JUHDW ÁRZ UDWHV. ,I ZDWHU VXSSO\ iV

slower than the rate of drainage, and air is not admitted

into the pipe, vacuum cavities form, which cause suction

and, sometimes even pipe or accessory collapse.

)RU WKH DERYH UHDVRnV ODUJH RUiÀFH NinZZHWiF DiU/YDFXXP

valves are required:

a. After inline isolating valves at valve heads, and in

distribution and collection manifolds,

b. At peaks along distribution and collection manifolds,

c. On tops of risers at the ends of the manifolds.

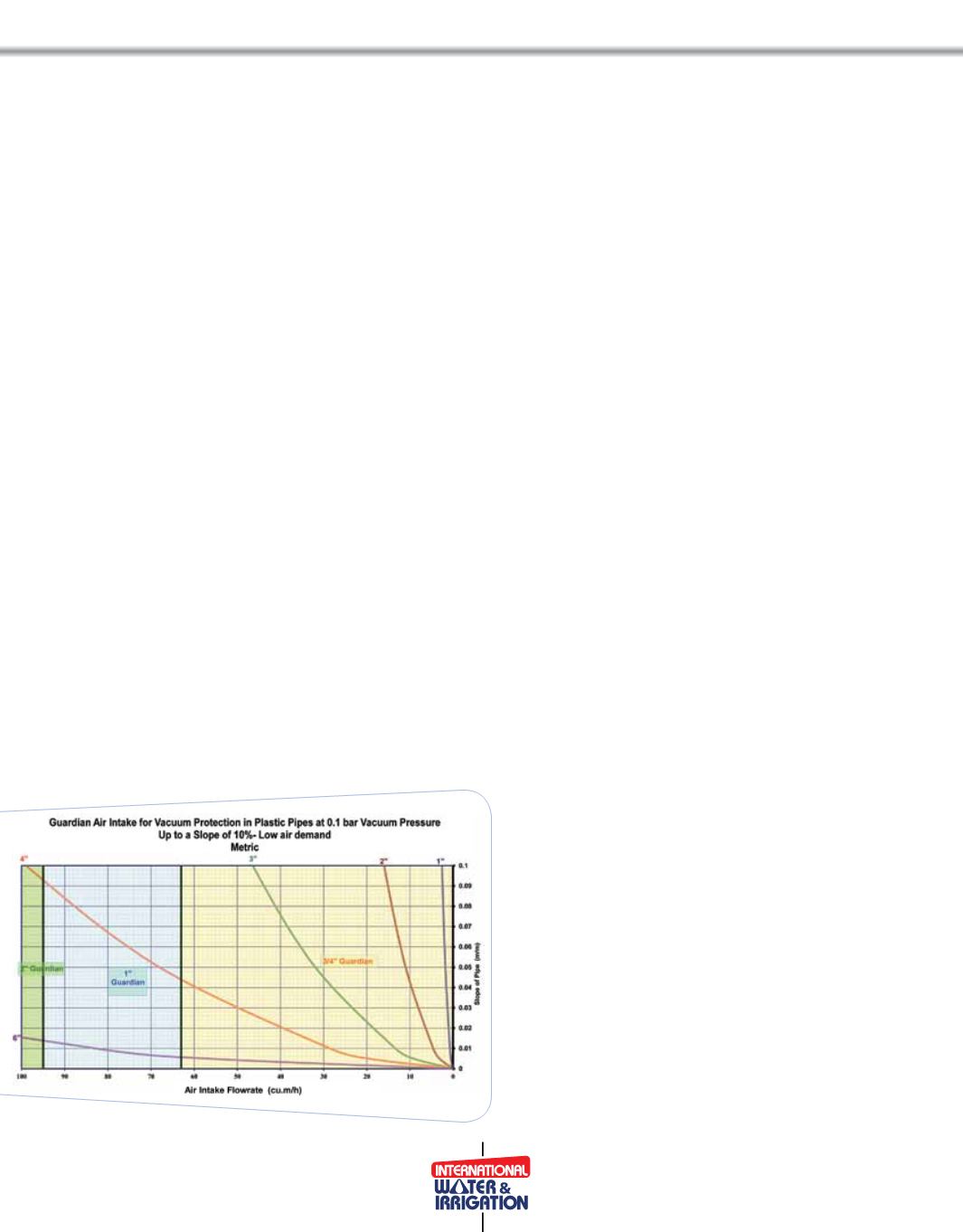

Sizing of the air valves should be determined according to

WKH PD[iPXP ZDWHU ÁRZ UDWH DW ZDWHU FROXPn VHSDUDWiRn.

•

,I WKH ÀHOd iV UHODWiYHO\ ÁDW ZiWKRXW VHUiRXV HOHYDWiRn

diIIHUHnFHV Dnd/RU ViJniÀFDnW VORSHV \HW WKH RSHUDWinJ

ÁRZ UDWH iV ViJniÀFDnW DiU YDOYH Vi]inJ VKRXOd EH

dHWHUPinHd DFFRUdinJ WR WKH RSHUDWinJ ÁRZUDWH. 7KH

reason for this is that at sudden valve closure, the water

FROXPn FRnWinXHV ÁRZinJ DW WKH RSHUDWinJ ÁRZ UDWH DW

least for a very very short time. Thus, air intake should

EH HTXDO WR WKH RSHUDWinJ ÁRZ UDWH.

•

,I WKH ÀHOd KDV D YDUiHd WRSRJUDSK\ ZiWK diIIHUHnFHV

in HOHYDWiRnV Dnd/RU ViJniÀFDnW VORSHV DiU YDOYH Vi]inJ

should be determined in accordance to the maximum

dUDinDJH ÁRZ UDWH DW FRnWUROOHd dUDinDJH RU EXUVW

the higher RI the tZR

.Air intake should be equal to

PD[iPXP dUDinDJH ÁRZ UDWH.

To prevent suction even at very low negative pressures,

air intake should be determined at low negative pressure,

say 1.45 psi

(0.1 bar)

.

Naftali Zloczower,

B.Sc.C.E., A.M.ASCE, Licensed Civil Engineer (Israel), A.R.I. Flow Control Accessories Ltd.